| |

|

INTEGRATING DATA - DRILLING |

|

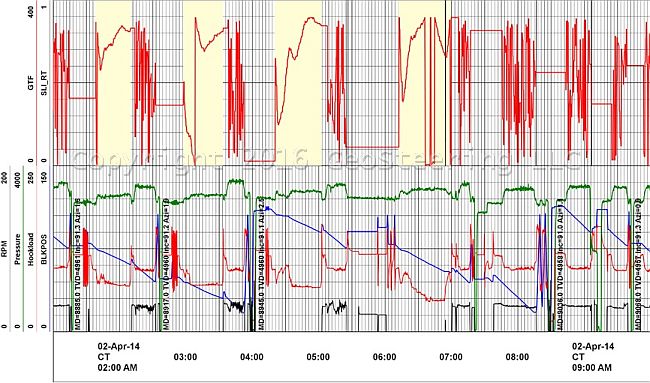

Time logs can be configured to show any drilling parameters measured by the rig instrumentation company.

MWD parameters - such as the motor toolface or the rotary steerable settings for requested and actual deflection and toolface - can be added, as seen on the example below which shows gravity toolface in the top track with surface drilling data below. The yellow intervals show the slides. |

| |

|

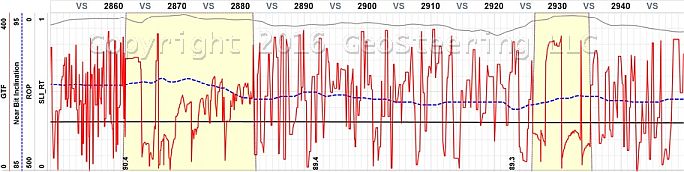

Time data can be gated to depth in real-time and displayed on depth-indexed logs. The example below allows the geosteering engineer to see how well the directional driller is holding toolface during slides as a function of the depth drilled.

|

| |

|

| |

On a recent well, a plot similar to this enabled a timely decision to be made to trip to set a larger bend in the motor. Both company man and DD were aware that the assembly was not giving the required build but the company man attributed this to poor directional work - that the DD was not holding the toolface - and did not want to trip. The plot on that well showed that the toolface was holding solid and that the bend needed to be increased.

|

|

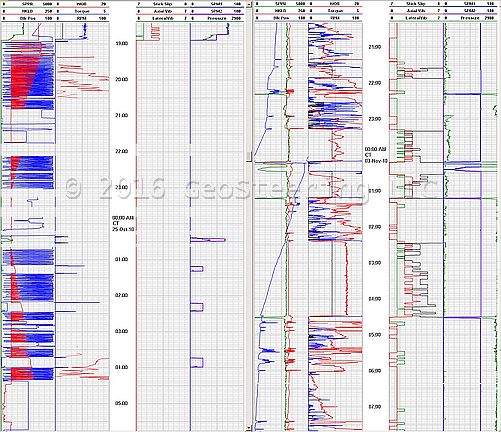

Event monitoring log displays - for example, for washouts, kicks, shocks, stuck pipe - can be configured and audible and visible alarms set.

Overall drilling efficiency can be monitored with built-in computations of time on bottom, off bottom, tripping in, tripping out and making connections.

The plot below shows shock and vibration data during a trip (left) and while drilling (right).

|

| |

|

|

|

| |

|